Cleaner cotton makes quality yarns – but how can spinners be sure of removing unwanted contaminants without wasting good fiber or hampering mill productivity?

Cleaner cotton makes quality yarns – but how can spinners be sure of removing unwanted contaminants without wasting good fiber or hampering mill productivity?

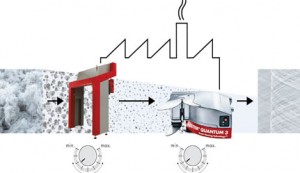

The acquisition of Jossi Systems AG by Uster Technologies has created the ‘Total Contamination Control’ concept. This combination of USTER® JOSSI VISION SHIELD and USTER® QUANTUM 3 offers spinners the highest level of foreign matter detection, together with lowest possible waste. When it comes to contamination in raw cotton, there are wide variations in how spinners need to react. Some of their yarn customers will demand a zero tolerance approach – for challenging end-uses such as white shirts – while others will not be so concerned, especially if they are serving less critical applications. But every spinner will recognize the need to avoid the risk of rejects and customer claims, by ensuring that all really disturbing faults are eradicated. Tailoring their yarns to precise quality specifications is the safest way to achieve this. For the most ‘contamination-sensitive’ customers, spinners face some serious choices. They could try to source only contaminationfree cotton, or attempt to locate and eradicate foreign matter manually, at the opening stage. However, neither of these options is really practical or reliable. In fact, automatic detection and removal of contamination offers the only effective solution – even better if a doubly-secure method can control unwanted material at both the start and end of the yarn production sequence. USTER offers exactly this, combining two leading-edge technologies in Total Contamination Control. First, the USTER® JOSSI VISION SHIELD, located immediately after the fine cleaner in the blowroom, takes out contaminants during the preparation stage. Then, after spinning, the USTER® QUANTUM 3 yarn clearers operate during winding to fine-tune contamination removal to meet the customer’s quality requirements. Total Contamination Control allows spinners to meet precise yarn specifications, while also managing the mill’s own productivity goals.

Sophisticated technologies behind contamination detection systems in fiber preparation and yarn clearing can handle all kind of foreign matter – natural and synthetic. Even White polypropylene (PP) is no problem for the USTER® JOSSI VISION SHIELD and the USTER® QUANTUM 3. The combination of these two systems guarantees the maximum contamination detection rate. But, should spinners worry that these systems might actually work too well – causing cotton to be wasted and damaging mill efficiency? Not at all, since the USTER® QUANTUM 3 has the power to distinguish between disturbing and non-disturbing defects, and cut out only what is necessary. What’s more, the system puts the production manager in the driving seat, steering the ideal route towards the required quality and the best productivity, with least waste. This is Total Contamination Control, balancing two systems at different stages of yarn production with USTER® JOSSI VISION SHIELD and USTER® QUANTUM 3. The spinner is in charge, guiding the choice between cotton tufts or spun yarn, lost raw material or splices…

One stop with a trusted partner

One stop with a trusted partner

The USTER name is a watchword for expertise and reliability throughout textiles. Its reputation over many decades as a trusted partner for the industry is now enhanced still further by the acquisition of Jossi Systems AG – creating the world’s only one-stop-shop for contamination control. The union embodies unrivaled knowhow and a commitment to continued development, in keeping with typical Swiss quality values. The one-stop-shop offers several advantages to customers. Servicing of the systems – already maintenance-friendly – is now unified, for simplicity and lower costs. USTER specialists are experts in both types of system, so are uniquely able to offer process optimization. Spinners can now be confident of meeting the needs of even the most demanding customers, while also taking care of their own profit management – a two-way business boost thanks to Total Contamination Control from USTER.