Made in Italy productıon and environmental awareness two leading companies with an internationall reputation for innovation present at ITMA ‘denim addicted’:A seamless eco-friendly capsule collection.

Made in Italy productıon and environmental awareness two leading companies with an internationall reputation for innovation present at ITMA ‘denim addicted’:A seamless eco-friendly capsule collection.

“Sustainable technology” is the main theme for ITMA 2015, one of the most important global events in the textile sector. And against this backdrop, Fulgar and Santoni – two high-profile Italy textile producers – make their presence felt with an innovative project that reflects their care for the environment. On the one hand latest generation machinery with reduced environmental impact – Santoni’s SM8/TOP2V – and on the other a 100% biological fibre, Evo® by Fulgar, a cutting edge product in the field of hi-tech biological materials and textiles. This prestigious combination has become the inspiration for a special project with the vocational training college “ITS Machina Lonati’. Santoni and Fulgar have brought in students from the ‘Fashion technologist Designers’ course to createa new, original interpretation of seamless products. This initiative will for the first time involve the use of Fulgar’s biological EVO® fibre. The creativity of talented young people – Alessio Bonetta and Valeria Dallan – is combined with the most recent technological innovations in the textile sector – also supporting environmental

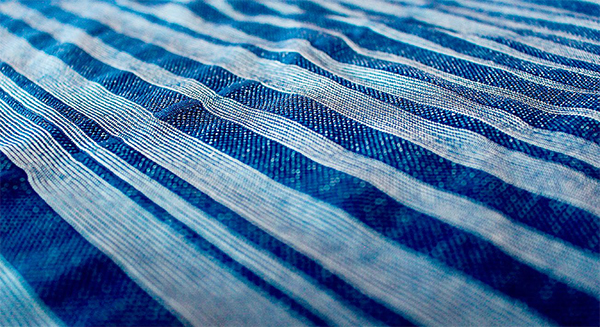

sustainability – to create an ‘eco-friendly’ Seamless collection. A series of denim-inspired garments that, thanks to Fulgar’s EVO® fibre – combines a green heart with a gutsy, high-performance personality for a modern urban look with even higher levels of comfort.

What is EVO® by Fulgar?

With the launch of EVO® Fulgar introduces a new way of producing yarn, a perfect synthesis of performance and environmental awareness. With 100% biological origins, Fulgar’s innovative EVO® yarn b oasts p roperties t hat i nclude l ower specific weight, excellent heat insulation performance, quick-drying, maximum breathability, odour control and bacteriostatic action, providing outstanding comfort, unique performance and intense respect for nature. Years of research into the highest engineering standards – in a manufacturing, environmental and social context – have led to the development of ‘EVO® by Fulgar’: an innovative high-performance fibre made of a biopolymer derived entirely from castor oil seed. This unique product – 100% biological – is set to revolutionise the sector. Suitable for all textile applications and an ideal solution for the sportswear world, EVO® by Fulgar is ultra- light, super stretch and extremely breathable. It’s also quick-drying, non-iron and offers natural thermal and bacteriostatic properties. These distinctive values and benefits ensure maximum comfort and unmatched performance, while retaining an intense eco-awareness. Its manufacture is supported by the cultivation of castor oil seeds that grow in arid regions not suited to other forms of agriculture. The biopolymer that forms the basic constituent of EVO® by Fulgar has no adverse impact on the human food chain, unlike many other biobased polymers that use natural products otherwise destined for the food and agriculture sector. Fulgar’s EVO® fibre highlights once again the brand’s deep concern for the environment and the future of the new generations, with an ever-increasing investment in research & development. Sustainability is, in fact, one of the crucial elements in Fulgar’s commitment to social responsibility, a philosophy based on the concept of “A better way to the Future”. This strategy is an outstanding example of corporate behaviour inspired by environmental awareness, working towards conservation and the improvement of the global ecosystem. Another highly successful product in this area is Q-Nova® by Fulgar, an innovative Nylon 6/6 fibre roduced with 99% recycled raw materials, and developed entirely by Fulgar using an innovative, eco-sustainable process.

How does the SANTONI SM8/TOP2V work?

It offers exceptional productivity, on average 30% higher than the current model and is incredibly energy efficient. It is due to technological innovation that allows our machinesto have a lower environmental footprint. This combined with improved ergonomic design for ease of servicing offers a potential 30% extra production for the same overhead space. Combine this with a 15% reduction in energy consumption and you have a machine offering improved environmental sustainability. It is also a very user-friendly model and comes equipped with completely new developed knitting parts; i.e. the yarn-finger group, a new sinker cap for high quality wool yarns and other natural yarns as well as improving plating possibilities, all of which contribute toan improved final product quality.