After receiving successful results at Techtextil Frankfurt and Shanghaitex, SSM announced their participation to the forthcoming Techtextil in Mumbai, India, from September 24th to 26th 2015.

After receiving successful results at Techtextil Frankfurt and Shanghaitex, SSM announced their participation to the forthcoming Techtextil in Mumbai, India, from September 24th to 26th 2015.

Techtextil is India’s leading fair for technical textiles and nonwoven products, which is the subsidiary of Techtextil Germany and covers twelve application areas, which comprehensively span the full range of modern textile technologies, where SSM will show their latest machine for technical yarns.The unique characteristics of tailor-made high performance yarns is helping such yarns to substitute other classical materials in large range of applications; thereby continually increasing the usage of technical textiles and consequently their consumption. Despite this overall positive scenario, production lot sizes can vary greatly; from large ones for standard yarns to small ones for specialties, managing such variances poses a challenge for any producer. The SSM DURO-TW precision winder for all technical yarns up to 50’000 dtex offers a new level of flexibility and winding quality in one machine; thereby ensuring the fulfillment of all customer requirements.

The assembly winder DURO-TD allows the plying of multiple ends/yarns; independent of them being of the same type or completely different. Optional intermingling guarantees loop-free twists as well as optimal unwinding during twisting. The ability to run closed precision winding enables higher package densities, thereby increasing the knot-free length.

SSM Success at Shanghaitex & Techtextil

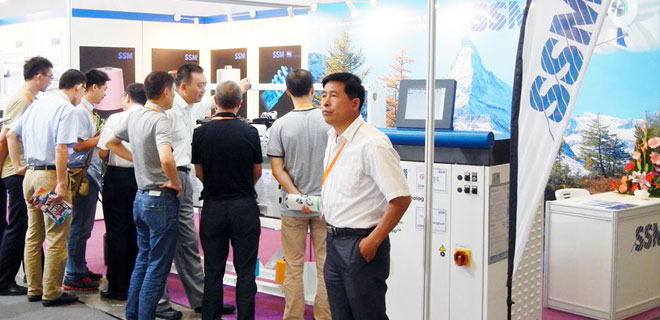

The 17th International Exhibition on Textile Industry (SHANGHAITEX 2015) has established its position as an important market place. SSM AG, the inventor of the electronic yarn traverse system, showed two applications from their well-known product range combining dyeing/rewinding and assembly winding applications. Five spindles showed the versatility of the SSM TW2plus-W precision package winder. Thanks to the electronic fastflex™ yarn laying technology, a high flexibility of producing a made-to-measure cross-wound package is possible. The ergonomic design and enduring technology cuts maintenance and service expenses down to a minimum. Improved winding performance and package quality are further generated by digitens™, the SSM technology for tension control during winding.

The sixth spindle presented the technology of the SSM TW2-D assembly winder. TW2 stands for innovative solutions, rugged technology and application of the essential. Not only enabled an improvement of the thread path, but also the overall simplification of the superior winder. Combined with the easy adaptation to a variety of yarns, the TW2-D is the assembly winding system for an economically and consistently fulfilling of customer requirements.

At Techtextil, held in May 4-7, 2015, SSM shared the booth with their representatives and other well-known European suppliers. During the show, SSM meet and discuss with many existing customers and also new, potential customers, showing interest in their products. Especially the brand new SSM DURO-TW, showed at Techtextil in Frankfurt, which is going to be shown also at the upcoming Techtextil India, gained great attention.

Besides of all these applications, SSM also provides solutions in Air Texturing, False Twist Texturing (SSM GIUDICI), Air Covering, Draw Winding, Yarn Singeing, Sewing Thread Winding and Conventional Covering. Once more the excellent reputation of SSM, as the market leader in the above-mentioned fields, was acknowledged and with their worldwide service network, SSM is able to provide the maximum return on customer’s investments.

As the market leader in these fields, SSM enjoys an excellent reputation. Furthermore SSM maintains a worldwide service network that ensures the training of their customer’s staff and the maximum return on customer’s investments.