Ak-Kim Kimya, founded in 1977 as a partnership of Akkök Holding, which is one of the long-established private sector bodies in Turkey, has been carrying on a business as a market leader in a lot of main chemicals and making production in high-tech modern sites for 38 years. Ak-Kim Kimya is making production of more than chemical substances in its production sites, of which capacity is 600 thousand tons per year. Ak-Kim Kimya Performance Chemicals – Sales and Marketing Group Manager, has answered out questions related to their work.

Ak-Kim Kimya, founded in 1977 as a partnership of Akkök Holding, which is one of the long-established private sector bodies in Turkey, has been carrying on a business as a market leader in a lot of main chemicals and making production in high-tech modern sites for 38 years. Ak-Kim Kimya is making production of more than chemical substances in its production sites, of which capacity is 600 thousand tons per year. Ak-Kim Kimya Performance Chemicals – Sales and Marketing Group Manager, has answered out questions related to their work.

Can you mention about your company and work in short as one of the leading companies in out sector?

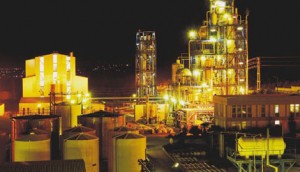

‘’We have nearly 20 production sites in three different locations, having high-technology, established in a 300-thousand-m2 area in Yalova and Çerkezköy. We have produced some chemical substances that are significant for our domestic industry and require advanced technology such as sodium metabisulphite, ammonium persulphate, dimethylacetamide, dimethylformamide, hydrogen peroxide, sodium percarbonate, for the first time in Turkey. Ak-Kim is also producing its performance chemicals with its own technology and thanks to its powerful know-how information and technical experience; it differs from its competitors. We are offering ‘integrated chemical solutions’ to our customers in line with their demands in all the sectors we are providing products as Ak-Kim. In addition, we have been selling our know-how and technologies to foreign companies and conducting all kinds of services from engineering and turnkey contract activities. We have founded various turnkey sites in Jordan, Pakistan, Saudi Arabia, Algeria and Greece until today. Apart from all of these, we have founded AKFERAL Company by making a partnership, in which each party has equal share, with Feralco, which in one of the second biggest producer of water chemicals and coagulant in Europe, in the last years. We are producing AKFERAL products which will make a great contribution to the development of the sector in Ak-Kim sites in Yalova. Moreover, in December 2014, we have taken a step to a new marker in the sector by purchasing Gizem Frit, one of the most significant enamelled and ceramic frit producers in the world.’’

Can you give some information about new products and their features, your company has presented to the market?

‘’ As Ak-Kim, we are providing different products to the market by producing chemicals oriented to personal care and cleaning sector with the contributions of inorganic and organic chemical and textile auxiliary materials and paper, water, cement grinding and concrete, thanks to our wide product range. We are making productions for industry at the utmost level; however, we are standing almost at every point of life. We have realized our Betain production site, of which capacity is 15.000 tons, in 2014. Ak-Kim has expanded its product scale within the scope of both detergent and cleaning industry, with Betain production, which is one of the input used in soaps, detergents and shampoos and it has developed its vast knowledge in order to produce the chemicals, which is not in its portfolio. At the same time, Ak-Kim is producing thickening products used in concentrate detergents, bleachers and paste detergents, oriented to this sector. Last year, we have developed ‘’No Fear’’ system in order to prevent perforation of fabrics in bleaching process by using our engineering, chemistry and textile process knowledge. This system has been the first integrated solution example developed by using three disciplines together in Turkey. Thanks to No Fear system, Prevention of fabric perforation in bleaching process in now provided. Some advantages of No Fear are improvement in fabric qualities in line with development in formula and process, ability to produce fabrics with high added value, capacity expansion and fabric and deadline profits, a result of working without any perforation. Besides, we have an international patent application related to performance chemicals.’

How do textile chemicals contribute to textile products, where are chemicals taking place in textile sector?

‘’ Textile Chemicals are being used within all the production steps textile products, reaching to the final user by starting natural and synthetic and fibre production. Lubricators are being used in fibre production while sizing agent are being used in fabric production, auxiliary materials are being used in bleaching steps and during colouring before colouring of the fabric and finally Textile Chemicals are being used in ‘finish’ processes, giving the final charm to the fabric. Therefore, chemicals are being used in all the steps in textile production.’’

What should be done about environment and human health? What is sustainability for you?

‘’ Sustainability has a great importance for Ak-Kim. We can say that we, As Ak-Kim, are in a leading position in this field in chemistry sector. Particularly, we are giving importance to environmental sustainability and aiming at producing new environment-friendly products so as to reduce chemical consumption. We, as Ak-Kim, are making some work without stopping in order to increase energy efficiency by following the most current technology in our production processes. These work’ being made systematically is very important for us. Therefore, a different body has been founded under the name of ‘Energy Management Body’ in order to develop the projects which increment energy efficiency, following and interpretation of electric-vapour-natural gas consumptions of Ak-Kim in a monthly or yearly basis and it is maintaining its work actively. As a transparent and sustainable company, Ak-Kim has made a lot of work in this field and is maintaining its reporting regularly within the frame of United Nations Global Principles Convention, signed in 2007 by Ak-Kim. Ak-Kim is the member of Global Compact for 7 years and has been entitled to get an approval in A level in the result of ‘Fourth Progress Report’ it has prepared in line with international reporting standards: GRI (Global Reporting Initiative) at the beginning of 2014.

Last year, in our agenda, there were some work related to our Sustainability report and our 5-year Sustainability goals which will take place in our strategy plan. Within this context, we have brought something new to the chemistry sector and we have made a workshop in order to form a road map by determining our sustainability strategies. With a workshop in which workers from different degrees has participated, we have aimed at determining the right work in sustainability field in the company and presenting our aspects, open to improvement. In the following step we have made a survey for our all shareholders and we have evaluated our prior issues in the eye of shareholders. We are in a close contact with our shareholders all the time and we have got a mission to be a body, which makes its shareholders glad all the time, by getting feedbacks with both customer and worker satisfactions surveys. In addition, we are trying to take place in the top cadre in sectorial foundations and counsels by supporting the sustainable growth of not only the company but also the sector and trying to shape the sector. In result of the work we have conducted, we can range our goals for the following 5 years; We will provide the foundation of energy management system and its improvement in the next years by receiving TS ISO 50001 certificate in 2015. Moreover, we will give priority to receive ISO 14064 certificate within the scope of sustainable emission management and to form/ provide continuousness of greenhouse gas calculations method. Ak-Kim will give a place to water saving projects, recycling of waste water, new water sources finding under the title of water management project within the scope of sustainable natural source management. Ak-Kim has been conducting special projects for creating worker fidelity in order to provide sustainable human resources management.’’

What is sector’s condition from the aspect of qualified employee? What is your opinion and what should be done about  this subject?

this subject?

‘’Like in all fast-growing sectors, we are having difficulty in finding qualified employee in Textile sector.’’

In which league is our Turkish chemistry industry taking place when we take World chemistry industry into consideration? What are the trends in textile chemicals?

‘’In 2005 chemistry sector in sectorial classification is in the 5th place after ready-garment, automotive, iron and nonferrous metals, electric and electronic sectors; From the end of 2014 it has been in 3th place after automotive and ready-garment. This condition expresses the fast growth and contribution to country economy of our sector. Production of products with high added value has a vital importance in order to reach 2023 goals and these goals will be realized with more Research and Development and innovation work and these work’ being commercialization. Product and process development oriented to water and energy saving in Research and Development works and special effects will rise to prominence, in particular.’’

How do you evaluate the sector in the following period?

‘’We think that it will be a tough year due to the changes in the neighbour countries and last developments in global economy. However, we also believe that textile sector, coming todays by dealing with different problems in different periods for years, will produce the required strategies and proceed on its own way by being strengthened.’’