SWITZERLAND – Heberlein, a leading supplier of air interlacing and air texturing jets, is set to make a significant impact at ITMA Asia + CITME 2024 with its latest innovations in DTY and ATY technology, including the introduction of the HemaJet-LB06. This new jet housing is a testament to the Swiss company’s commitment to being a comprehensive, one-stop provider for air-texturing processes.

Rising Demand for Air-Textured Yarns in China

In China, the air-textured yarn (ATY) sector has gained prominence as a specialized niche within synthetic yarn production. Despite the industry’s cyclical nature, it is currently experiencing a peak, driven by strong demand from fashion, home textiles, and industrial applications, both domestically and for export. Heberlein has reported robust business performance in the ATY market in China and anticipates a strong turnout at their booth during the upcoming ITMA Asia + CITME 2024 in Shanghai.

Heberlein’s Innovations in DTY and ATY

Among the highlights of Heberlein’s showcase is the new DTY jet insert X44.29, the smallest of its kind, designed for applications up to 30dtex—setting a new standard in precision and efficiency.

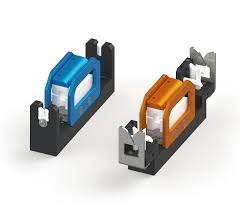

Visitors to the Heberlein booth, located in hall 7 at stand D25, will also have the opportunity to explore the HemaJet-LB06, an economic and versatile solution for ATY processes. This robust jet housing is compatible with all Heberlein jet core series (T, A, and S), making it adaptable to a wide range of air texturing requirements. The adjustable distance between the impact body and the jet core allows for precise control, ensuring optimal results across various applications.

Heberlein’s jet cores have been a reliable choice in the ATY industry for decades, catering to diverse needs, from compact and uniform yarns ranging from 30dtex to 3,000dtex, to softer textile yarns achieved through higher overfeed potential. Customers can confidently select from Heberlein’s extensive jet core portfolio, knowing that the housing will seamlessly accommodate their chosen core.

Cost-Efficient Solutions for the Chinese Market

Even in a market like China, where energy costs are relatively low, Heberlein’s APe series has demonstrated significant savings potential. By reducing compressed air consumption by 15% without compromising knot quality, the APe series has caught the attention of DTY yarn producers. According to Heberlein’s calculations, based on data from GlobalPetrolPrices.com, a texturizer in China can save approximately one dollar per hour. For a machine equipped with APe series jets (288 positions), this translates to daily savings of $24.30, based on a 24-hour operation at 3 bar pressure.

The APe series is designed for a wide application range, from 67 dtex to 800 dtex, with the new APe141 jet insert enabling high interlacing density of 80 to 160 FP/m, delivering light to medium stability.

PolyJet Series: Leading the Way in Spinning Technology

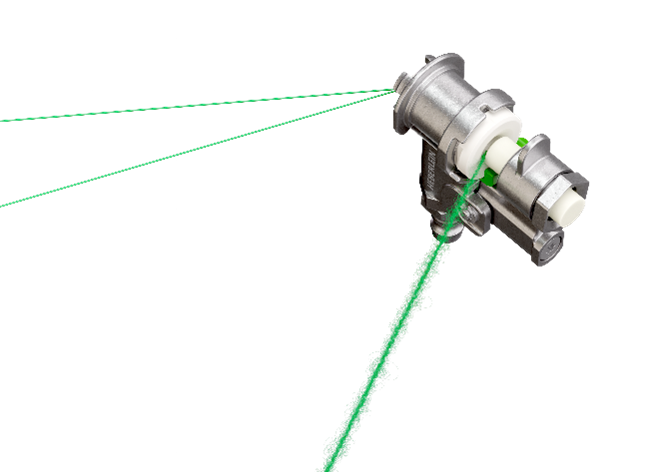

Heberlein’s PolyJet-SP3 and PolyJet-TG-3 air interlacing jets are globally recognized for their superior performance in spinning textile yarns. The PolyJet-TG-3-HP405A/WO70 (TopAir) is particularly noteworthy for producing yarns with exceptional evenness, uniform interlacing density, and strong, reliable knots, making it ideal for high-tenacity yarns (HT and HMLS).

The PolyJet series stands out with its innovative quick-release system, allowing jet pack changes within seconds using a simple 180° turn. Its compact design and roll bar to protect ceramic surfaces further enhance its appeal.

Heberlein’s cutting-edge solutions reaffirm their position as a leader in the synthetic yarn industry, offering unmatched precision, efficiency, and reliability for both the Chinese and global markets.