The MAX GLASS ECO, launched by KARL MAYER’s Technical Textiles Business Unit, has quickly become a reliable and cost-effective solution for producing standard reinforcement textiles from glass fibers, particularly non-crimp fabrics used in the wind power industry. This versatile newcomer, which can be customized with various optional functions to meet different application needs, offers short amortization times and high efficiency. Operating at a maximum speed of 1,800 min⁻¹, it can produce up to 410 meters per hour with a working width of 101 inches.

Since its debut at JEC World in March of this year, the MAX GLASS ECO has made a significant impact on the composite market, securing several purchase agreements. Orders have been placed by customers in India, and even larger quantities have been requested by Chinese clients. The demonstration models in KARL MAYER GROUP’s customer centers in Changzhou and Chemnitz have already been sold, but the unit at KARL MAYER Technische Textilien in Saxony will remain available for processing trials and performance tests until September.

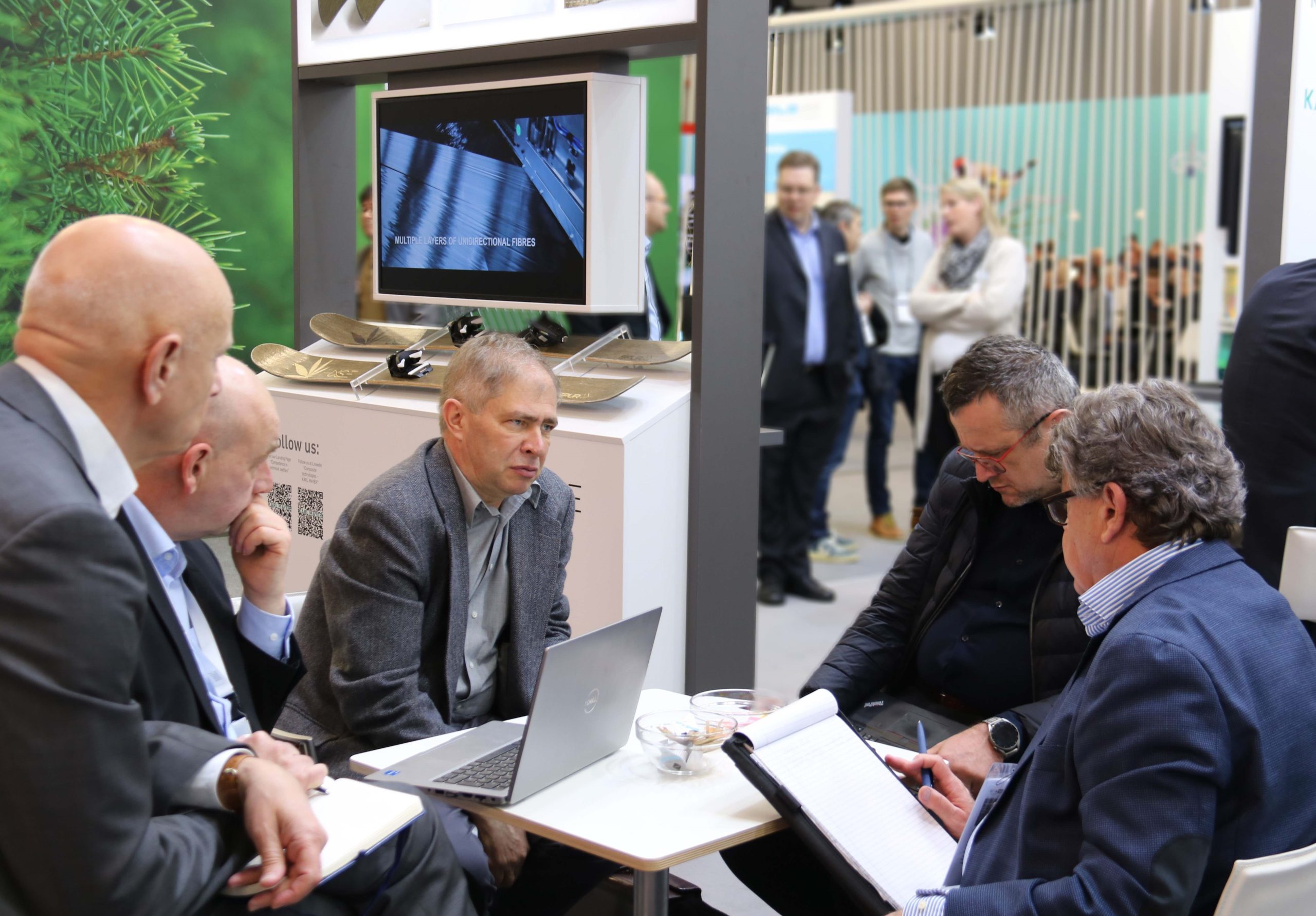

Interest in the MAX GLASS ECO extends beyond Asia, with growing attention in Eastern Europe as well. At Techtextil 2024 in Frankfurt, the machine was the subject of numerous discussions with Ralf Schramm, Sales Manager at KARL MAYER Technische Textilien for the region. “I had many conversations about the machine’s capabilities,” says Schramm, “and there were even customers with specific purchase requests, including the Polish company Rymatex, known for its high-quality, professional solutions for the composites industry.”

Beth Dufresne from Owens Corning’s glass reinforcements business highlights what makes the MAX GLASS ECO stand out: “KARL MAYER has integrated many proven solutions from its multiaxial machine line, bringing the advantages of these systems into the MAX GLASS ECO.” As one of KARL MAYER’s earliest customers in the multiaxial sector, Owens Corning recognizes the value of this innovative approach. After being introduced to the MAX GLASS ECO through presentations and video material, Dufresne was particularly impressed by its comprehensive, best-in-class design.