Freudenberg Nonwovens is presenting innovations in wound care at INDEX 2014.

Freudenberg Nonwovens is presenting innovations in wound care at INDEX 2014.

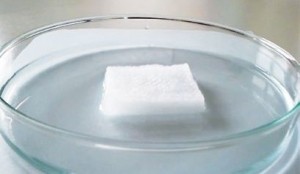

With over 30 years’ experience in the medical sector, the company is well prepared to tackle any challenge: A comprehensive portfolio for traditional wound care is complemented by solutions for ostomy applications. Freudenberg Nonwovens systematically focuses on innovations, from antibacterial finishing to the use of chitosan fibers in advanced wound care products, and offers tailor-made solutions – not just for the medical industry. In the past knitted fabrics were mainly used to care for wounds; today, though, it is hard to imagine wound care without nonwovens. Freudenberg and its long-standing know-how have been instrumental in bringing about the transition to functional nonwovens as the base material for wound care. The company is not only presenting the latest developments in traditional wound care at INDEX 2014, but is also showcasing numerous innovations in the field of advanced wound care, where the wound environment must be kept moist. That is why Freudenberg primarily uses highly-absorbent fibers. The material adapts perfectly to fit the wound bed – which makes life much easier for chronic wound sufferers in particular. One major innovation is the use of chitosan fibers. In combination with hydroactive nonwovens, this biopolymer brings new perspectives for the healing process and is already proving its worth in practice. “Our experts have extremely extensive material know-how. We process all types of fibers and offer several options for individual solutions in addition to standard products,” explains Dr. Oliver Heneric, Business Segment Management Medical Europe at Freudenberg Nonwovens. “That makes us the market leader in ostomy applications, for example, and we are also pressing ahead with the latest developments in transdermal applications in the USA.” Research into transdermal solutions is based on cooperation with Japan Vilene Company, a Freudenberg joint venture partner with extensive know-how in this segment.

Cross-industry trends: Lightweight materials

Experience gained in different fields of application generates valuable synergies that bring benefits to customers everywhere. In the Hygiene segment, Freudenberg offers ultra-light and skin-friendly topsheets, backsheets and acquisition distribution layers for baby diapers, feminine care and adult incontinence applications. These nonwovens have excellent wear comfort thanks to the cotton-like structure. Special solutions such as eco-friendly ADLs complete the product portfolio for the hygiene segment.

Developing extremely light materials is a predominant trend throughout industry in general: Freudenberg has developed an ultra-light product variant of Evolon® with a 3D structure, a material with an extremely soft touch and high volume that also has the cleaning efficiency of a microfilament cloth. The general-purpose microfilament can be used for both wet and dry applications: In industry for the surface treatment of cars, for example, or in professional cleaning, as well as in the consumer sector, for instance as LCD wet wipes or for cosmetic wipes. Evolon® has an ultraviolet protection factor of 80. This is the maximum ultraviolet protection factor pursuant to the latest UV Standard 801 – and therefore makes the nonwoven an interesting option for textile manufacturers as well as the makers of sunshades, awnings, etc. Visitors to Stand 2127 can see for themselves just how effective Evolon is as a printing medium.

Acoustic nonwovens for enhanced comfort

Acoustic nonwovens fulfill an important function in car interiors: They help to absorb noise and thus increase comfort. The ultra-light SoundTex® acoustic nonwoven reduces the thickness and weight of the sound-absorbing material while delivering the same acoustic performance. This nonwoven can be finished in many ways, e.g. for flame or media resistance, and it also complies with the stringent material requirements set by the automotive industry. Optimum processing is guaranteed thanks to cut edges that will not fray plus good formability.

Bicomponent fine filaments for individual solutions

Freudenberg Nonwovens aims to offer tailor-made solutions in all of its target markets. The newly-developed bicomponent fine filaments are particularly well suited for use in numerous applications in many industrial sectors. Different polymers can be combined in one filament during the manufacturing process. In addition, these bicomponent fibers can be mixed with monofibers, thus creating several different property profiles for these spunlaids. The materials can be used in packaging, coating substrates, reinforcements, cover materials, hygiene and cosmetic products, and automotive applications. Freudenberg Nonwovens adjusts the composition of the fibers – and thus the material characteristics – to suit requirements in order to develop the optimum individual solutions for many different applications.