Effe Endustri developed new and innovative products that are going to be launched in ITMA 2015 Exhibition are focusing on Green and ustainable Technology. Effe Endustri is preparing to attract attention in ITMA 2015 with projects that will bring major acquisitions to its users.

Effe Endustri developed new and innovative products that are going to be launched in ITMA 2015 Exhibition are focusing on Green and ustainable Technology. Effe Endustri is preparing to attract attention in ITMA 2015 with projects that will bring major acquisitions to its users.

Effe Endustri Company which designs and manufactures technological units for machines such as rotation, digital printing, compacting, dryer, washing and mainly stenter is drawing attention with its new and innovative technologies along with its expertise in textile machine accessories manufacturing.New products that are added recently to list of products and being prepared to launch worldwide at ITMA 2015 are focusing on green and sustainable technology. Effe Endustri is ready to provide service and products on the international stage with project that will bring major acquisitions to its users…

Electro static filter unit worldwide launch in ITMA 2015

Newly developed Electro Static Filter for stenter machines is on top of the presented product list in ITMA 2015 for the sector representatives. Designing Nature Friendly Green Technologies and gaining them to textile sector is EFFE Endustri Company’s main purpose and Electro Static Filter manufactured with unique and able to meet all expectations design, is on top of the products for customers all around the world. The unit which is designed to filter oil and solvent in exhaust gas that emitted through atmosphere from stenter machine chimneys, filters exhaust gas that has temperature between 140-190 °C according to the process circumstances and then emit as steam through the atmosphere in stenter machine applications. Besides preventing the wasted gases harm human health and environment, heat saving is also provided thanks to this application. Exhaust gas enters the unit with 140-190 °C temperature and temperature get decreased below 70°C in exchanger. Warm water gained by decreasing the exhaust gas temperature in exchanger unit, can be used for various purposes in establishment. In some applications, warm water gained by exchanger prior to this unit, can be transferred to stenter machine chambers in order to save energy. Solid particles in wasted gases that coming through electro static filter are hold in manual filters. Wasted oil and solvents that occur from finishing and heat setting processes of especially polyester fabric in exhaust gases, are being hold with electro static method and they are getting available to be used in various purposes.

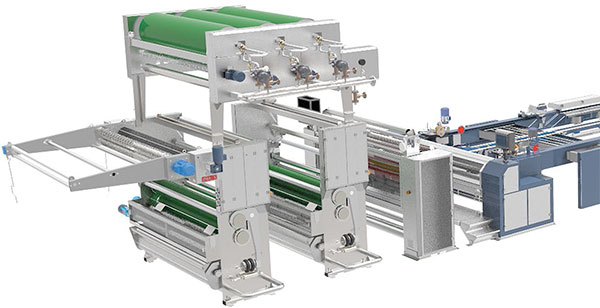

EF-SR2 type dye padder rapid, eco friendly, budget friendly dye technology

Dye padder which designing and manufacturing activities completed by Effe provides fast, nature friendly and economical solutions with its high technological hydraulic roller for woven and knitted fabrics in various processes. Its dye-ing technology is sustainable, low investment costed, easy to use featured and efficient thanks to homogenous squeezing effect of double hydraulic rollers. It is used for open width fabric dyeing with stretching method or cold bleaching before dyeing process of knitted and woven fabrics. Due to the horizontally positioned2 pcs rollers with hydraulic oil pressure working, edgemiddle- edge difference is completely eliminated and homogenous squeezing effect is gained.

The newly developed infrared fabric edge control sensor

In recent years, EFFE Industry has made great technological investments in fabric edge control sensors used in Stenter, Pin Chain Tenter Frames, Compacting, Drying, Coating and similar textile machines and produced different types of high performance sensors. Our full band edge control sensors used in Fabric Centering and Guiding Units, edge control sensors used in stenter and compacting machines inputs function with a high performance even under the heavy working conditions. Our most recently designed and produced EF-ECU model IR Fabric Edge Control Sensor completed design tests and real practice in operations successfully and the product has been launched and opened to sale.

Add value to your existing machines with modifications

Modifications on machines with high investment values used in textile establishments such as Stenter, Compacting, Drying, Digital and Rotation Printing Machines with new technological units is one of the primary engineering services offered by EFFE Endustri. Increasing the performance and power generation of your existing finishing machines is a result of applying innovative and state of art equipment and units successfully. You can contact us for projects and engineering services such as modification on pinning groups of stenter machines and any type of pin chain tender frames, edge trimming and gum applications, complete inlet applications for printing machines, inlet/outlet units and drying chambers for digital printing machines and moving your complete machineries in within the shortest time.

EFFE is one step ahead in edge trimming practices

The edge trimming units, developed and mass produced by EFFE Endustri, are used with success in various textile finishing processes.  Different types of edge trimming units produced by EFFE are mainly as follows according to their intended use; a- Disc and photocell controlled edge trimming units used for cotton and blended fabrics processed with stenter and compacting machines. b- Special edge trimming units with dia-mond blades which ensures longer trimming for polyester and viscose fabrics. c- Ultrasonic edge trimming units used for special types of fabric, especially in automotive industry, in order to prevent fringe formation. d- Alternative edge trimming units used for heavyweight textiles; carpets and similar textiles, coated textiles etc. You can get detailed information from our process engineers about practices that will minimize your edge trimming wastage and learn the latest innovations in different types of edge practices for new machines that you are planning to invest on or modification purpose of your existing machines.

Different types of edge trimming units produced by EFFE are mainly as follows according to their intended use; a- Disc and photocell controlled edge trimming units used for cotton and blended fabrics processed with stenter and compacting machines. b- Special edge trimming units with dia-mond blades which ensures longer trimming for polyester and viscose fabrics. c- Ultrasonic edge trimming units used for special types of fabric, especially in automotive industry, in order to prevent fringe formation. d- Alternative edge trimming units used for heavyweight textiles; carpets and similar textiles, coated textiles etc. You can get detailed information from our process engineers about practices that will minimize your edge trimming wastage and learn the latest innovations in different types of edge practices for new machines that you are planning to invest on or modification purpose of your existing machines.

Brushing unit and dust collection unit makes difference

Over many years, there are many different equipment used for collection of dusts and fibers on fabrics and raising its production quality under operating conditions. Brushing and Dust Collection Unit applications are not used for all finishing machineries separately, it may be impossible financially. That’s why, EF-FTE Model, which is designed for Raw Fabrics Preparation Machines, provides the most economical and effective solution with its Brushing and Dust Collection Unit. The unit provides a decrease in processing and improve of quality by using on the Singeing Machines. It is also used with maximum performance at the inlet of Rotation and Filmdruck Printing Machines for all type of knitted and woven fabric.