Comez is a global leader in the technology of crochet and warp knitting machines, specializing in narrow fabric technology and since October 2012 combined its business activity with Jakob Müller AG.

Comez is a global leader in the technology of crochet and warp knitting machines, specializing in narrow fabric technology and since October 2012 combined its business activity with Jakob Müller AG.

After that, started working with Bilol Machinery Represantation as their agency in Turkey, which have been Jakob Müller’s agency for over half of a century. The resourcefulness and experience which have allowed Comez to build a solid position in the sector over 50 years in business derive from its maintaining a direct and constant contact with its customers. Comez has always proposed new machine models that are capable of producing innovative textile products, in line with the demands for increasing machinery customisation, enabling textiles designers to obtain results which enhance their creativity by constantly multiplying their range of products according to fashion demands. Producers of narrow fabrics find in Comez a highly qualified and attentive partner, providing assistance in their production of:

• laces, ribbons, bands (also with logos and customised graphics), for underwear, lingerie, foundation garments, sportswear and accessories

• passementerie, fringes, edges, trimmings used in home textiles and on outer garments

• fancy yarns

• shawls, scarves, fabrics for outerwear

• technical and medical articles.

Comez machines have always been sought after and held in high esteem for three main reasons:

• their “user-friendly operation” which is deemed a distinguishing feature compared to machinery from the competition. This user-friendliness is the result of intelligent building design that is attentive to the needs of the users, allowing for a cor rect and profitable use of each machine by any level of operator (even operators possessing low skill levels).

• great “versatility”, perceived as the possibility of processing a near unlimited series of yarn types without difficulty (natural, man-made, synthetic, special yarns, of fine or coarse count) and of producing a wide assortment of articles on a single machine model, obtained simply by altering the machine’s settings or changing a few parts. This advantage is of great interest to customers, since they cannot find it with the competition’s machinery, and because it enables them to create an extensive range of textiles with a single production means while counting on continuous production (overcoming changes in fashion tastes and market trends), enabling them to be competitive in new market segments.

• prompt after-sales service which enables a maximum level of efficiency in machine production output

As important as the quality of the machines are the assistance services supplied by Comez:

• consultancy services for research and test projects targeting the production of narrow fabrics

• the possibility of conducting testing jointly with customers to assess the feasibility of new products

• customisation of machines, tailor-made to the user’s specific needs

• machine demonstrations and trial tests

• availability of training courses. The aim is to increase the fields in which Comez machines can be applied and, as a result, allow users to penetrate and compete in a wider range of textile sectors, both traditional and new. Among the range of Comez crochet knitting machines, two models are especially worth mentioning.

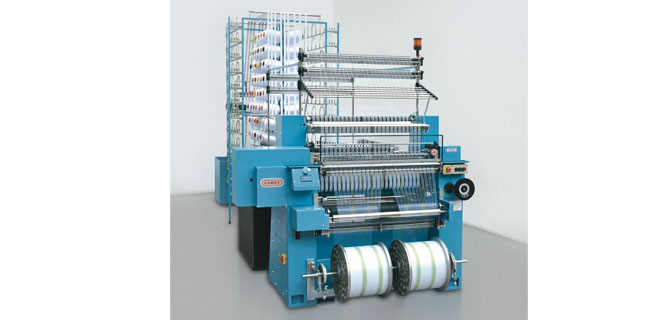

COMEZ 829/B3

High speed crochet knitting machine for the specialised production of both elastic and non-elastic bands. It comes in gauges from 12 to 15 n.p.i., with working width of up to 824.5 mm, uses bearded needles and is fitted with 2 weft bars and the heddle bar for elastic threads, mechanically controlled. By means of a special device, with carbon fibre bars, weft movements of up to 150 mm can be effected, adapting the machine speed to the movement. This machine features easiness of use and accessibility, so that all operations for regulations and maintenance are facilitated.

COMEZTRONIC CT-16B/600

High efficiency electronic crochet knitting machine for the production of a wide range of very complex laces, both elastic and non-elastic. Featuring high versatility, productivity and quick article changeover times, this machine expresses at top levels the high quality of the Comez technology, representing a unique production means at disposal of the manufacturers of sophisticated articles for underwear. It is available in gauges 12, 20 and 24 n.p.i., with a 600 mm working width, uses bearded needles and is fitted with 16 weft bars with electronic control. The high number of bars and the electronic operation system allow elaborate patterns to be created, with very long pattern repeats.