Mayer & Cie. is based in Albstadt, Germany. At its headquarters, machinery for manufacturing MCT’s knitting machines will undergo a modernisation. Furthermore, the company is hiring further technical staff.

Mayer & Cie. is based in Albstadt, Germany. At its headquarters, machinery for manufacturing MCT’s knitting machines will undergo a modernisation. Furthermore, the company is hiring further technical staff.

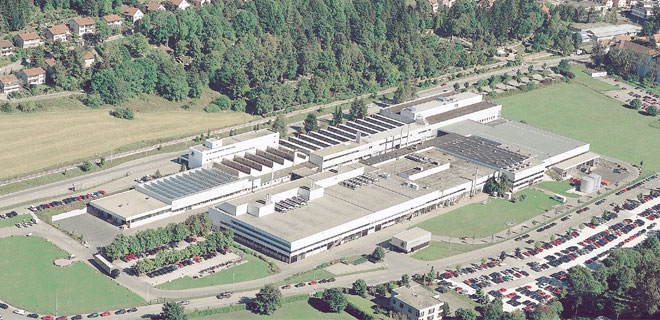

The long-established knitting machinery manufacturer from Albstadt, Germany, Mayer & Cie. (MCT) is planning considerable investments in technology, facilities and personnel for the years 2015 and 2016. The largest individual share will go to the expansion and modernisation of MCT’s headquarters in Germany. Planned are investments of altogether about four million Euros in order to expand the capacities in the production line in all locations, to modernise the company’s own machinery and comply with new software requirements. On the agenda is also the increase in size of the subsidiaries in China and the Czech Republic.

„We are very pleased with the company’s performance in the past years”, states Benjamin Mayer, Managing Director at Mayer & Cie. „In 2014 we achieved a turnover of roughly 90 million Euros over the entire group which is seven percent more than in the preceding year. We want to utilise this success to set the right courses for the future.” The Albstadt-based knitting machinery manufacturer is aiming at accomplishing a good balance between strengthening its headquarters and expanding its production capacities close to the market.

Emphasis On İnvestments At Company’s Headquarters

Foundation of the company’s future success and expansion is laid in Germany – that is agreed upon at Mayer & Cie. For the headquarters of the family-run business in Albstadt investments of about three million Euros are budgeted. On top of that employee numbers will further be increased just as in the years before. Above all in assembly and production there will be new personnel to attend to the company’s full order books.

A restructuring and modernisation of the building equipment at the headquarters is another part of the investment plan. The heating and cooling systems have to be revised in order to reduce energy consumption. For MCT energy efficiency draws a continuous line, starting at production and assembly and leading up to the final product, the knitting machine. It is with good reason that the company is a member of the Blue Competence initiative and engaged to fulfill authoritative criteria for sustainability.

The machinery that is used for manufacturing knitting machines in Albstadt-Tailfingen will also undergo a modernisation. For this sector there is a budget of about one million Euros. „In order to consistently supply our customers with optimum quality we regularly bring the machine pool we use for assembly and production up to date” states Managing Director Benjamin Mayer. It is in Albstadt where the key parts of the knitting machine are manufactured, above all the knitting head. Actually all knitting machines from Mayer & Cie., with very few exceptions, are ‚Made in Germany‘.

Key Markets Mainly Outside Of Europe

Investments of a total of about one million Euros are budgeted for the expansion of the capacities of Mayer & Cie.‘s subsidiaries in the Czech Vsetin and in the Chinese province Shanghai. That is how MCT brings parts of its production closer to its key markets. After all, since many years, the majority of MCT’s customers cannot be found in Germany anymore but in Asia. Only Turkey, MCT’s most important key market forms an exception. 210 knitting machines worth about 16 million Euro were sold there in 2014. In Asia the sales quantity has continuously been increasing for years, above all in India and China. Here the demand for machines of the mid-range price segment is very large and they preferably have to be available on short notice. „Our Asian customers often order a machine only after they have accepted an order themselves which they cannot complete in due time with their existing machinery” said Benjamin Mayer. „If we want to be successful, we need to be able to react quickly and flexibly to these short-term orders. On top of that, this market is very price sensitive.”

Mayer & Cie. accommodates those needs by expanding its site in China. This is where the MSC 3.2, a single jersey machine developed particularly for the Chinese market is assembled. With this machine Mayer & Cie. has been able to increase its share in the Chinese market significantly in the past years. In 2014 MCT sold a total of about 200 machines worth approximately eight million Euros. Another increase of 20 to 30 percent is expected for 2015. 50 of the MSC 3.2 II manufactured in Shanghai, which Benjamin Mayer acknowledges very good prospects also in other Asian countries, like for instance in Bangladesh, are said to be available for export in 2015. Besides that MCT wants to develop an equivalent double jersey machine and get it manufactured in the Chinese Mayer plant as well. In order to be able to meet these requirements, the relocation to larger premises was completed in April this year.

At the site in Vsetin in the Czech Republic, which MCT acquired in 2011, larger premises are also needed. At this location they manufacture the successful machines of the S- and D-series including some key components. With this product line introduced in 2004 MCT could significantly expand its customer base in the premium price segment both in the single and double jersey sector. Particularly in India machines of these lines enjoy great popularity; MCT could sell around 220 machines worth about 8.7 million Euros in 2014, 125 machines more than in the preceding year. In order to be prepared for the expected further increase in demand, Mayer & Cie. is planning the new construction of a 5000 square meter size plant in Vsetin. Start of construction is to be during the first half of the year 2015 yet, the completion is scheduled for end of 2016. Presently 60 people work for Mayer & Cie. in the Czech Republic, with tendency to rise.

Mayer & Cie. Shipped 70,000th Knitting Machine

Knitting machine manufacturer Mayer & Cie. (MCT) of Albstadt, Germany, delivered the 70,000th circular knitting machine in the company’s 110-year history to a lingerie manufacturer Speidel in Bodelshausen, Albstadt, Germany. It was an FV 2.0 double jersey machine and the customer was knitwear manufacturer Speidel GmbH. Speidel is using the machine at its knitting factory in Bodelshausen, where the main production focus is on high-quality single jersey and fine rib lingerie, most of which is manufactured in body widths to make it optimally comfortable to wear. For years Speidel has ordered the knitting machines it needs solely from Mayer & Cie. in Albstadt-Tailfingen.

“We feel greatly honoured that the seventy thousandth Mayer & Cie. knitting machine was supplied to us,” said Hans-Jürgen Speidel, Production Manager at Speidel GmbH and the man in charge of the nearly 130 knitting machines at the company’s factory. “Good and reliable partners on your doorstep are a stroke of good luck, not least because of the short distances, the personal contact and the close collaboration. At the same time, of course, the presence of innovative, forward-looking companies counts toward the value and continued existence of a domestic industry location.”

Constant Quality Generates High Level Of Customer Loyalty

Speidel knits between 90 and 100 tonnes of material per month, all for its own lingerie product lines, so the main focus – along with reliable machine performance – is on constant high quality of the knitwear. Speidel mostly uses single jersey and fine rib machines that produce circular knitted fabric by the metre in standard body widths of between 12 and 20 inches and a variety of cotton blends such as cotton and Modal or cotton and Elasthan. Less familiar materials like bamboo or a yarn based on algae also find their way via the knitting machine into the company’s latest lingerie collection.

Mayer & Cie. knitting machines developed and manufactured in Albstadt are mainly responsible for Speidel’s knitwear output. Over the past 15 years in particular, a large number of knitting machines with the green MCT logo have joined the machine pool. Speidel has nearly doubled the number of its knitting machines over this period, relying entirely on Mayer & Cie. The most important machines in use at the Speidel factory are the MV 4-3.2 II and the FV 2.0, both of which are highly productive machines for the lingerie sector. The jubilee machine is an FV 2.0.

Albert Mauz, the manager of Speidel’s knitting factory, has no difficulty in naming the reason for the company’s loyalty to Mayer & Cie. “We appreciate the consistently high quality, the high level of machinery expertise and the continuity we can be sure of at Mayer & Cie. Special requirements that we have of our new machines for production reasons are reliably taken into consideration and implemented at the development stage.”

Mayer & Cie. likewise greatly appreciates the longstanding, successful collaboration with Speidel. Marcus Mayer, Managing Director and Production Manager at MCT, said: “We naturally feel proud of delivering the seventy thousandth knitting machine to the customer, and we are especially proud that we are able to celebrate this occasion together with Speidel, a family firm like our own with a long tradition of innovation and a clear awareness of the merits of ‘Quality Made in Germany’.”