Red Carpet has been founded in June 2012 with the aim to provide innovative solutions in the textile finishing machinery field and is based on competence, reliability and experience of his staff.

Red Carpet has been founded in June 2012 with the aim to provide innovative solutions in the textile finishing machinery field and is based on competence, reliability and experience of his staff.

Strongly convinced that “much has been done but more needs to be done” Red Carpet has created an industrial project where, the proximity to the market and the ability to listen and grasp its open issues, brought out of needs not fully met by the machines actually offered by the market. A careful study of these variables that have a positive influence on the “hand” of woolen fabrics has driven the “design activities” of its technical staff and led to the creation of three models of decatizers that are distinguished by performances, flexibility of use, innovative content and allows not only to get an higher quality (in terms of “hand” and stabilization) in comparison to what obtainable with similar decatizers, but also to reduce the number of steps in the production flow and therefore considerable savings for the end user along with a production speed, on average higher than the one possible with similar decatizers.

Wool Basic

Continuous atmospheric decatizer for both, knitted and woven fabrics. In general the continuous atmospheric decatizer represents a “must” in most of the finishing mills. For this reason Red Carpet has provided a “cutting edge” machine, so simple in principle as reliable and functional in its use. Thanks to the suction of the decatizing cylinder controlled by inverter it is possible to adjust the speed of the fans directly from the control panel, with the most effective and accurate settings and with the additional benefit of reduced energy consumption. Additionally, the innovative electronic control system of the motorized cylinders (BERS) allows recovering the energy generated by the braking motor that would be otherwise lost, wasted as heat. The specially designed steaming box together with the finely controlled suction, grant a moderate but effective action on different finishing field, from worsted to woolen , and with a wide range of fibres, from natural to synthetics and their blends. WOOL BASIC enhances the characteristics of each type of fibre preparing the same optimally for the treatment in the KD, thus avoiding sagging as preparation to the KD. WOOL BASIC restores softness and gives a bulkier handle to the treated fabrics removing the excess lustre created on the KD as finishing decatizing.

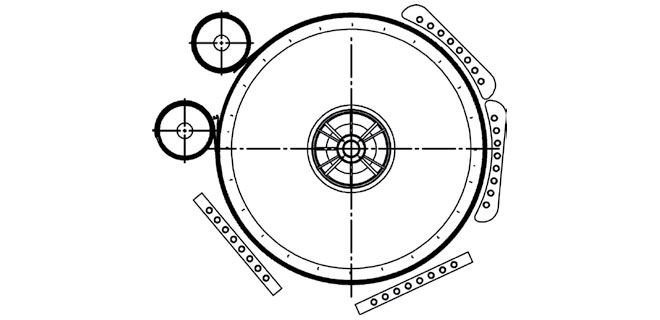

Wool Power

Continuous decatizing machine with steam under pressure for both, woven and knitted fabrics. Power, reliability and versatility become a winning mix in this decatizer with steam under pressure mod: WOOL POWER. After an accurate research , RED CARPET has developed a technologically advanced decatizer, capable to improve what has been so far obtained on similar machines, while solving some of the problems noticed in the traditional decatizing process. WOOL POWER not only enables operation to adjust thickness and “hand” of the treated fabrics thus avoiding the sagging problem as preparation to the KD but also to correct the stiff “hand” typical of the treatment in the autoclave thus obtaining a fabric ennobled and enriched by excellent tailorability characteristics as finish decatising after the KD operation. In such cases of the replacement of the KD, for 100% wool fabrics, which require light KD treatment, it will be possible to obtain ennobled fabrics “ready to the needle” with of a shorter production cycle; for wool blends fabrics and for 100% synthetic fabrics (PES, PES / Viscose, …), thus eliminating the typical problems of batch processes.

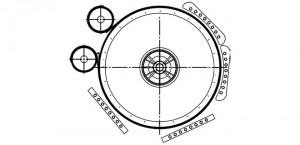

Wool Tech

Continuous decatizing machine with steam under pressure for both, woven and knitted fabrics. The combined actions of under pressure and atmospheric decatizer , reach an optimal synergy with WOOL TECH, an extremely versatile decatizer conceived and designed by the technical staff of Red Carpet to treat any type of article and fibre. The particular configuration of WOOL TECH has been thought to cancel the slightest tension on the treated fabric both, at the entry and at the exit. During the treatment, the fabric is transported between two blankets, thus avoiding tensions and consequent fabric elongation. All the above makes this decatizer suitable for the treatment of every kind of article, particularly knitted fabrics.The transportation between two blankets guarantees a perfect treatment homogeneity on both sides thus removing the problem of the appearance diversity between the two sides of the fabric. In addition to what foreseen on the Wool Power for woven fabrics, in case of knitted fabrics with natural and/or synthetic fibres, the Wool tech replaces the autoclave operation thus solving the typical problems of batch processes granting at the same time stability, handle and excellent aesthetics characteristics.