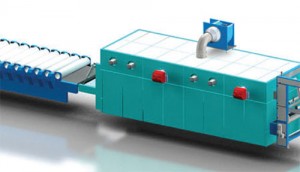

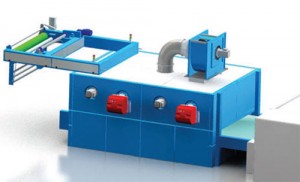

Effe Industry continues its R&D studies carried out according to current customer demands with its new and economic solution based applications for the inlets of digital printing machines, rotation printing machines and film-druck printing machines especially to reduce the transfer times of delicate knittings and woven fabrics . These applications provided for quality production and decreasing the production costs being a must in customer satisfaction and competition can be used for inlets of any model of printing machines. Within these applications, according to fabric features and process conditions, EF-FCU Pneumatic system centering units with stave, EF-BVU Dedusting unit with brush, EF-LC Loadcell application, EF-MED-F Pneumatic edge spreader unit, EF-FCU-B Servo-motor controlled centering and guiding units with stave, EF-ECU-B Edge control sensor, EF-MED-S Last edge spreader units and EF-MT Center drive dock winding systems are used.

Effe Industry continues its R&D studies carried out according to current customer demands with its new and economic solution based applications for the inlets of digital printing machines, rotation printing machines and film-druck printing machines especially to reduce the transfer times of delicate knittings and woven fabrics . These applications provided for quality production and decreasing the production costs being a must in customer satisfaction and competition can be used for inlets of any model of printing machines. Within these applications, according to fabric features and process conditions, EF-FCU Pneumatic system centering units with stave, EF-BVU Dedusting unit with brush, EF-LC Loadcell application, EF-MED-F Pneumatic edge spreader unit, EF-FCU-B Servo-motor controlled centering and guiding units with stave, EF-ECU-B Edge control sensor, EF-MED-S Last edge spreader units and EF-MT Center drive dock winding systems are used.

Thanks to these applications, it is possible to convey any type of woven and delicate knitting fabrics to the blanket of printing machines in the desired fabric width without tension. Thus, longtidunal and transverse pattern defects encountered during the printing processes in which especially the rapport length has to be fixed and elongation problems of fabrics come to an end. By the help of newly designed modular and energy saver dedusting unit with brush as a result of R&D studies, problems like elongation of fabrics during brushing and being unable to clean dust on the fabric as required experienced with classic dedusting units with brush are prevented. Especially in the rotation printing machines, all the problems that occur due to folded edges prevented with mechanic last edge spreader applications applied before printing roller at the last point where fabric is pinned on the blanket. In some rotation printing machine models, problems arising from the fabric covering an unnecessary long distance during its transfer to printing blanket from the inlet are being solved by fabric input modifications to reduce transferring distance. With the tension controlled loadcell systems added to conn digital printers to rotation printing machines input centering units, it becomes possible to transfer fabrics without tension. Center drive dock winding systems created for the inlets of digital printers of which the production rates increase to a great extent thanks to rapidly renewed technologies are demanded in the sector very much recently and help bringing production quality to the top.

Thanks to these applications, it is possible to convey any type of woven and delicate knitting fabrics to the blanket of printing machines in the desired fabric width without tension. Thus, longtidunal and transverse pattern defects encountered during the printing processes in which especially the rapport length has to be fixed and elongation problems of fabrics come to an end. By the help of newly designed modular and energy saver dedusting unit with brush as a result of R&D studies, problems like elongation of fabrics during brushing and being unable to clean dust on the fabric as required experienced with classic dedusting units with brush are prevented. Especially in the rotation printing machines, all the problems that occur due to folded edges prevented with mechanic last edge spreader applications applied before printing roller at the last point where fabric is pinned on the blanket. In some rotation printing machine models, problems arising from the fabric covering an unnecessary long distance during its transfer to printing blanket from the inlet are being solved by fabric input modifications to reduce transferring distance. With the tension controlled loadcell systems added to conn digital printers to rotation printing machines input centering units, it becomes possible to transfer fabrics without tension. Center drive dock winding systems created for the inlets of digital printers of which the production rates increase to a great extent thanks to rapidly renewed technologies are demanded in the sector very much recently and help bringing production quality to the top.