SHIMA SEIKI MFG., LTD., the renowned Japanese manufacturer of computerized knitting machines, is set to participate in the 15th CAITME Central Asian International Textile Machinery Exhibition in Tashkent, Uzbekistan. Partnering with its Turkish sales representative, TETAS A.S., SHIMA SEIKI will bring the latest advancements in flat knitting technology to this important event.

Uzbekistan’s textile industry has been undergoing a significant transformation, shifting from being primarily a raw material supplier to an emerging garment exporter. This transition presents exciting opportunities for the adoption of new technologies. In response, SHIMA SEIKI will introduce its cutting-edge N.SSR®112 computerized flat knitting machine. This machine is designed to provide a blend of advanced technology and cost-effectiveness, featuring innovations such as the R2CARRIAGE® for faster carriage returns, a spring-type moveable sinker, and the DSCS® Digital Stitch Control System. With these features, along with Made-in-Japan quality, reliability, and productivity, the N.SSR®112 meets the high demands of the global fashion industry. It also offers the unique capability of gaugeless knitting, allowing multiple gauges to be knit within a single garment.

For the first time in Uzbekistan, SHIMA SEIKI will also present the new N.SSR®072 computerized jacquard collar machine, which specializes in the efficient production of shaped collars based on computer-generated designs.

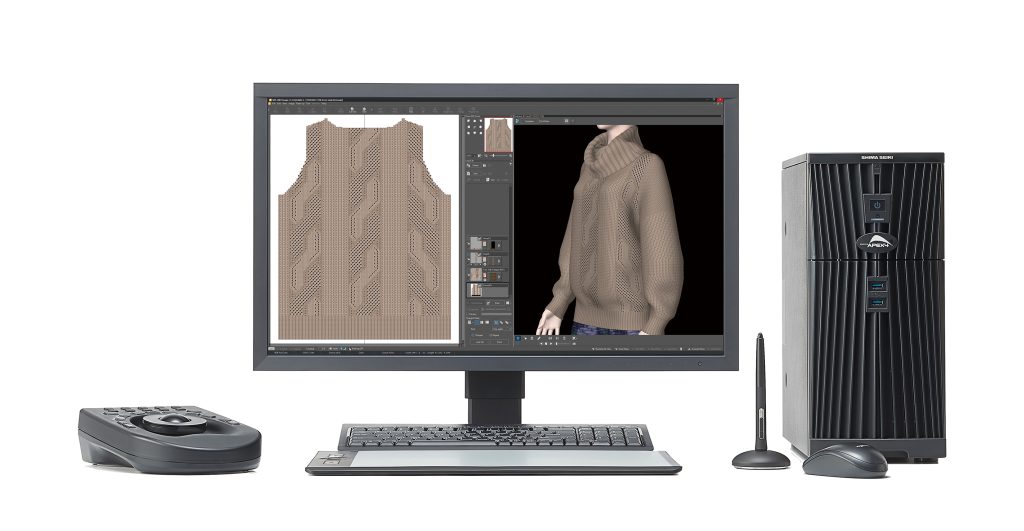

In addition to these machines, SHIMA SEIKI will demonstrate its SDS®-ONE APEX4 design system. As the cornerstone of the company’s “Total Fashion System” concept, SDS®-ONE APEX4 offers end-to-end support throughout the production supply chain, seamlessly integrating everything from yarn development and product planning to production and sales promotion. The system is particularly effective in improving the design evaluation process through its ultra-realistic simulation capabilities. By enabling virtual samples to replace physical ones, the SDS®-ONE APEX4 reduces time, costs, and material waste, facilitating the digital transformation of the fashion supply chain and promoting sustainable manufacturing practices.